The Diamond Tool Holder

A highly versatile lathe tool holder that’s easy to use, easy to resharpen and uses standard inexpensive square HSS tool bits.

If you are not sure what size holder is suitable for your lathe please scroll down the page for more information.

8mm (5/16″) Tool Height (11mm Shank)

10mm (3/8″) Tool Height (12.7mm Shank)

12mm (1/2″) Tool Height (15mm Shank)

16mm (5/8″) Tool Height (17mm Shank)

Tool Bits, Clamps and Spares

20mm (3/4″) Tool Height (19mm Shank)

How to select the correct size Diamond Tool Holder for your lathe.

All the Diamond Tool Holders are sized by tool height (this is the optimal height from the bottom of the tool shank to the tip of the tool bit) rather than shank height.

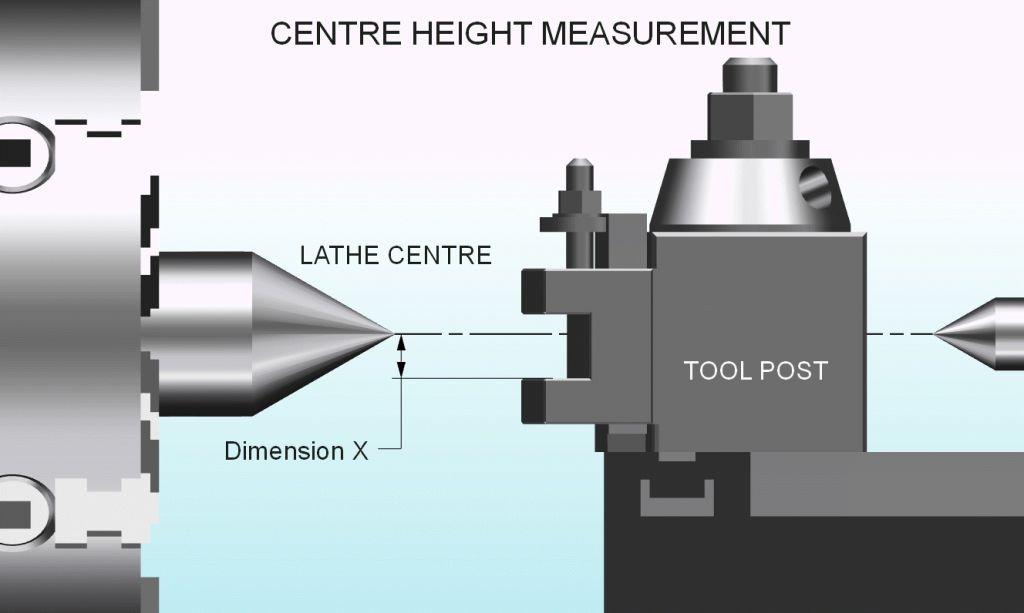

To select the correct size tool for your lathe, take a measurement from the centreline of the lathe spindle to the surface that the tool shank will sit on in your tool post (dimension X).

If you are using a 4-way or non adjustable tool post.

Select a Diamond Tool Holder for your lathe that is either the same tool height or less than dimension X. Don’t select a holder that is too large. It is much easier to raise a smaller holder with a packer than it is to bring an oversize holder down. The tool bit can be adjusted up or down a small amount anyway for fine adjustment of centre height.

Example – If Dimension X = 13mm

Select the 12mm Diamond Tool Holder and you can lift the tool bit up an extra 1mm so no packing piece is required.

If you are using an adjustable (quick change) type tool post.

- First check the height and width of the slot in the tool post holder to make sure the tool selected will fit the gap.

- Lower the tool post holder to about 3mm(1/8″) from the bottom of its lowest setting. This will give the maximum rigidity whilst still allowing some adjustment up or down.

- Measure dimension X with a steel rule to obtain the tool height.

- The Diamond Tool Holder size you select should be the same or less than dimension X. It is then a simple matter to raise the tool post holder up a bit higher to achieve centre height if needs be.

The Diamond Tool Holder utilises a standard square or round tool bit held at a tangential angle to the workpiece, instead of the usual horizontal orientation. Holding the tool bit in this position provides all the clearance angles required for general cutting purposes, leaving only the top rake (angle) to be put on using the grinding jig that comes with the kit.

Due to this tangential angle, all the cutting forces will be transferred down through the length of the tool tip. This together with a body cast in 4140 heat treated steel makes for a very rigid tool.

The Diamond Tool Holder utilises a standard piece of square section HSS. The three smaller size holders use 1/4″ tool bits and the two larger holders use 5/16″ tool bits. HSS Tool bits are inexpensive and easily available from any engineering supplies. One tool bit blank is supplied with each kit.

Resharpening is fast and simple using the supplied grinding jig. Just clamp the tool bit in the jig and run it across a regular bench grinder after setting the correct height of the grinder tool rest/ table. Due to the design of the holder, this is the only face that needs grinding.

Using the same jig, it is easy to grind an additional facet on the tool bit for a 55 or 60 degree screw cutting tip by using the V groove at the front of the jig. The relevant holders will also accept 1/4″ or 5/16″ diameter round tool bits for use as a round nose tool and the jig will sharpen this too.

For more information on the Diamond Tool Holder watch the video of the tool in action below.